When a blocked decant pipe nearly brought production to a standstill at a Western Australian mine, Goldfields Protective Coatings (GPC) stepped in to solve the issue. Located in Norseman—an area known for extreme conditions—the process water pond had filled with slurry after a thickener malfunction during the commissioning of a new plant. The water feed dropped to just 15% capacity, forcing the use of temporary pumps to keep operations running.

The challenge: harsh conditions and complex logistics

⚠️ Temperatures reaching 50°C

⚠️ Hyper-saline water posing corrosion risks,

⚠️ Logistical concerns included the disposal site for the slurry, which had not been confirmed at the time of planning.

These variables made estimating a project timeline difficult. GPC initially provided a 12-day estimate based on similar work completed using water cannons, though noted this would depend on many external factors.

The solution: Gerotto Lombrico S robot

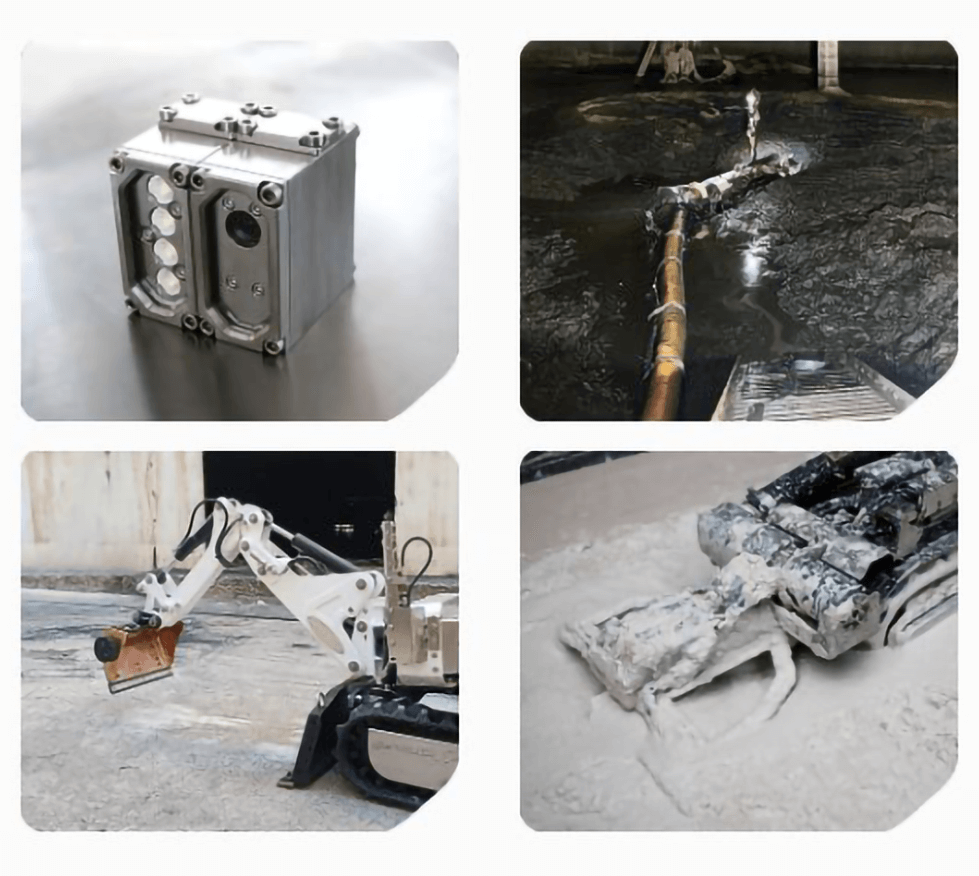

Specialists in removing solids and liquids from tanks and ponds, GPC turned to robotic technology supplied by KOR, exclusive distributor of Gerotto products in Australia and New Zealand.

Instead of relying on labour-intensive or water-heavy methods, GPC deployed the Gerotto Lombrico S:

🔵Remote-controlled robot built from stainless steel to withstand hyper-saline environments.

🔵Operated from an air-conditioned control room via monitors and cameras, the robot eliminated the need for personnel to enter the pond.

🔵 Significantly reduced water usage, far less than traditional method.

The result: 5.2 million litres of slurry removed safely

✅ Work began with vacuum trucks removing material around the pond to create a safe operating area. Once cleared, the Lombrico S was deployed into the pond, successfully removing 5.2 million litres of slurry in 14 days.

✅The slight extension from the original 12-day estimate was due to a mid-project change in disposal site, requiring travel to a location over 30 minutes away. Crucially, the project was completed with zero incidents, equipment failures, or downtime.

✅ GPC completed it safely and under budget, restoring the site to full operating capacity.

GPC testimonial

Mick Darwen, Operations Manager at GPC, shared:

“The great advantage of using the Gerotto robot is that it can be placed exactly where the slurry is and therefore can soften up the product instead of having to use a vacuum hose in the one spot and having to hose it.

It also cuts down on fatigue, as our crew were able to operate from an air-conditioned truck running off a TV screen, as well as increasing safety by 100 percent as none of the crew had to enter the pond and the manual handling of hoses was not an issue as the robot did all the work”.

Learn more about Gerotto robotic solutions

This case study highlights how robotic cleaning equipment can solve urgent, complex problems safely and more cost-effectively than traditional methods. For operations facing harsh environments, water limitations, or confined space challenges, the Gerotto robotic solutions offer a proven, scalable solution.

Articles and news

Latest articles

Subscribe to the newsletter to stay updated on the latest news