Debris Vacuuming: How to Make the Most of a Suction Excavator

According to ANCE data, the construction sector experienced an investment boom in renovations during the 2021-2022 biennium (+25%) and then stabilized in 2023. In the same year, civil and industrial construction saw an 8.9% increase in the number of building permits for renovations. Additionally, the strong PNRR investments in urban regeneration must be considered, which require activities for the management of rubble and construction debris.

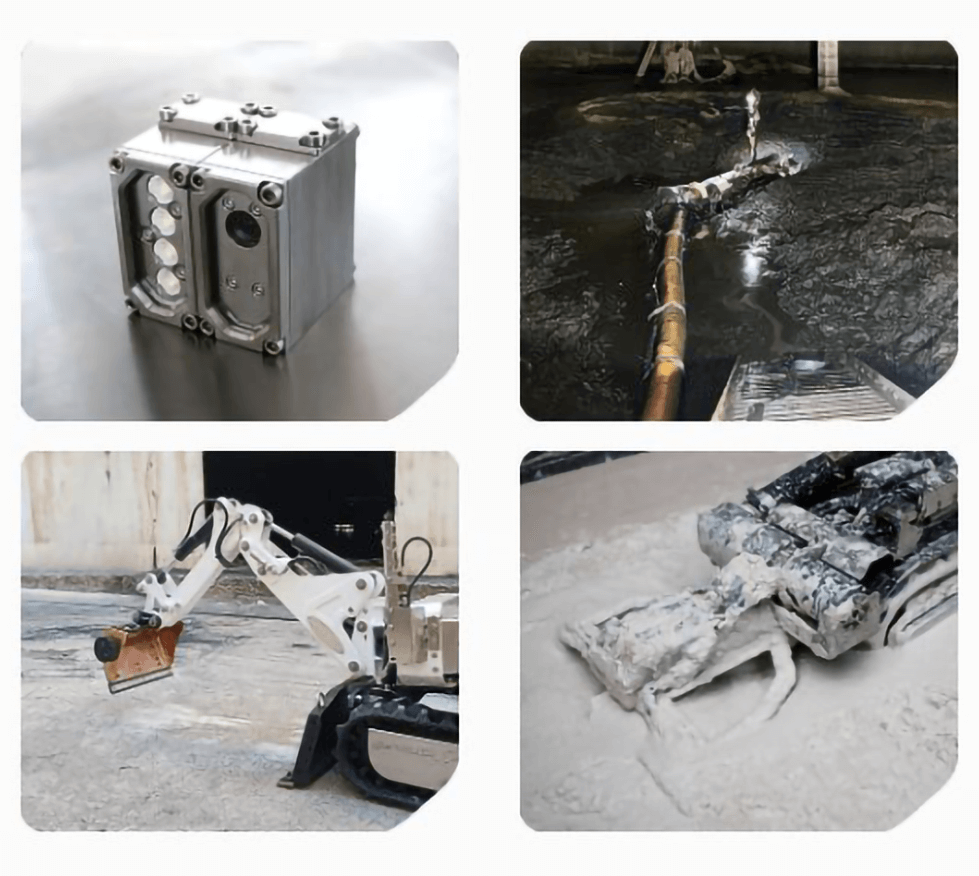

The Suction Excavator for Debris Removal

In the construction sector, the topic of renovations and demolitions is particularly sensitive. The suction of rubble and debris is a crucial phase, both from an environmental and logistical perspective. The suction excavator is a machine that has revolutionized the world of excavation and construction. The idea of using air as a vector to create a vortex capable of removing any type of material has represented a paradigm shift and a new mindset for the industry. The ability to dry-suction solid materials, even of significant size—thanks to the 250 mm suction hose—allows for optimal use of this technology, especially when it comes to removing rubble and debris.

Construction Site Logistics

Whether it’s the demolition of private homes, renovations, or the decommissioning of industrial plants, using a suction excavator is a choice that offers significant environmental and logistical benefits.

These machines reduce the need for additional construction equipment. For example, in the renovation of an apartment in a city center, a traditional setup would require a container to collect debris, a chute to connect the floor to the container, a truck to transport the container, and multiple handling operations. The suction excavator, on the other hand, serves as both a debris chute (thanks to the suction hose) and a container (thanks to its built-in storage). This results in:

- Extremely fast site setup times

- Minimal transportation trips

- Very limited ground space usage

But what exactly is inside a suction excavator?

The Suction Excavator: Power and Flexibility

In essence, pneumatic suction utilizes air as a vector to remove materials, whether solid, liquid, or sludge. With a dual turbine system, the machine generates an airflow of up to 42,000 m³/h and a maximum vacuum of 55,000 Pascals. Thanks to this power, suction excavators can remove materials from distances of up to 120 meters and depths of up to 45 meters. The suction hose enables precise and deep excavation, preventing damage to existing pipelines and underground utilities. Additionally, thanks to dry suction technology, operations can be carried out without contaminating road surfaces or surrounding areas.

Storage of Suctioned Material

Once collected, the material is directed into a storage container with a maximum capacity of 8 m³, equipped with a patented air filtration system capable of filtering particles down to 0.2 microns, ensuring zero dust dispersion and maintaining a safe and healthy work environment. The suctioned material can be either stored on-site in collection basins or discharged into roll-off containers. These features allow for a reduction in excavation size, time, and volume while utilizing a single machine that suctions, loads, and transports materials—resulting in a cleaner job site, maximum safety, and fewer operators needed.

For over 20 years, Gerotto has been the exclusive distributor of RSP Gmbh, one of the pioneers in this technology. Contact us for a quote on new machines or used machines.

Gerotto TRUCKS

The best solution for subsurface utility excavation, working in potentially contaminated environments, and operating in confined spaces.

Articles and news

Latest articles

Subscribe to the newsletter to stay updated on the latest news