The Bacchiglione Reclamation Consortium chose Gerotto for an operation to restore, consolidate and repair 100 metres of pipeline. The intervention was strategic for the hydraulic safety of the territory.

Highlights

- 100 metres of pipeline cleaned up.

- Operators’ safety thanks to the robots.

- Reduction in waste volume thanks to suction excavators.

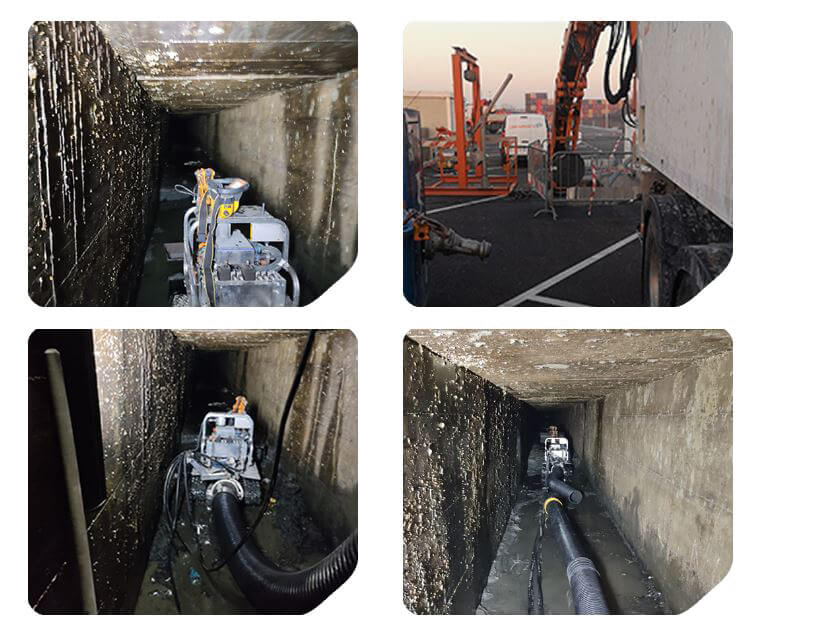

The Bacchiglione Consortium, as part of a hydraulic safety project for the territory, carried out extraordinary maintenance on a water infrastructure that is strategic for the area and for the entire southern part of the industrial zone of Padua. This is a highly urbanised area and is very important for the consortium network, as it is a crucial node for the distribution of irrigation resources. The Consortium chose Gerotto’s services to remove the material accumulated inside the Orsaro Canal siphon barrel, located within the Padua interport area at the initial section of the Padua-Venice waterway.

The task: to remove the material deposited in the confined space

The siphon barrel is an artefact, dating back to the 1980s, approximately 100 metres long; it consists of two juxtaposed reinforced concrete pipes measuring two metres high and one and a half metres wide. The cleaning operations, after drying out the duct and inspecting the cask, were carried out by teams of operators from Gerotto Solutions – the Gerotto company’s Business Unit dedicated to material reclamation and suction operations.

Robots and suction excavators for safe and sustainable removal

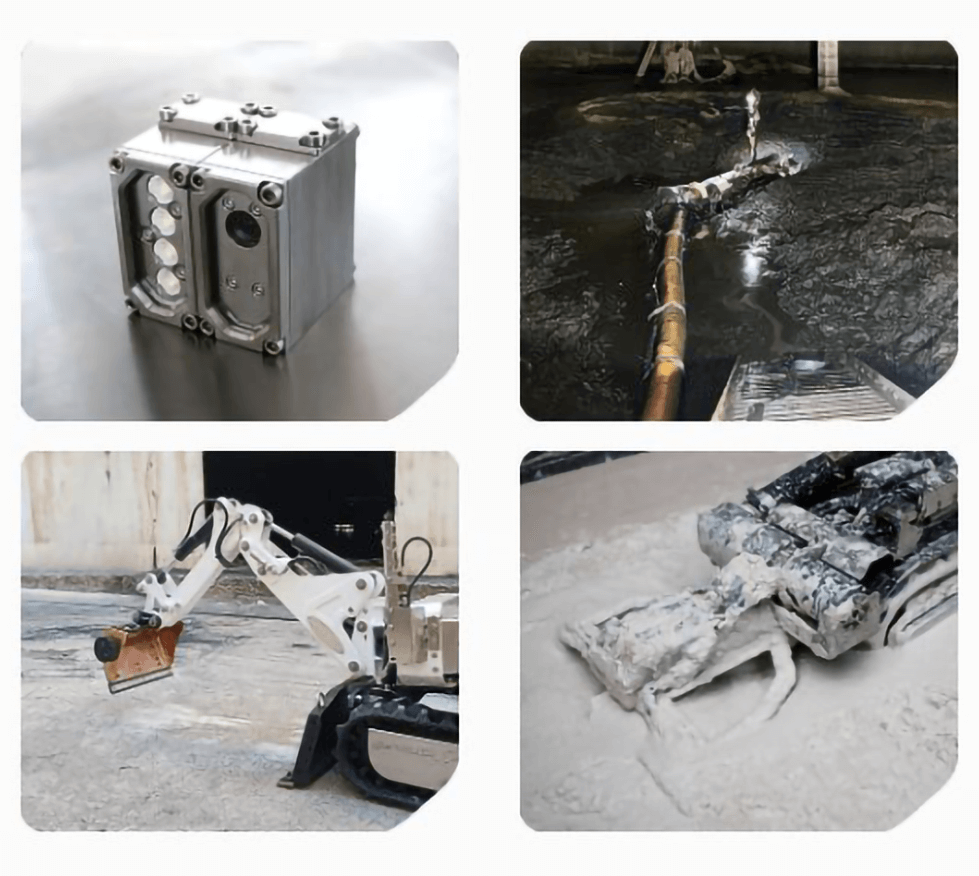

For the intervention, Gerotto’s teams used a Gatto RC radio-controlled robot, produced by the company itself with the Gerotto Robotics Business Unit: this is a special machine on tracks, equipped with LED lights and cameras that allow the robot to be remotely manoeuvred by monitoring movements on a control unit located outside. The robot is equipped with a frontal bucket that carries the material to the suction mouth located between the two tracks. The suction excavator, placed outside the siphon barrel, thanks to the powerful turbines and the suction hose of about 100 m connected to the robot, sucked up all the material – especially soil, sludge and debris deposited over the years. The peculiarity of this technology, which uses air as a vector, is precisely that it can suck up any material dry, thus without having to add water to fluidify it. This greatly reduces the volume of waste generated and minimises the use of high-pressure water to break down the material. Furthermore, the fact that operators are employed outside the siphon barrel increases the safety of the site and the working conditions of the personnel.

“Hydraulic safety is strategic for the territories and the economy,’ comments Alessandro Gerotto, CEO of the company. The recent floods in Emilia-Romagna unfortunately remind us that it is only through far-sighted planning and constant and scrupulous maintenance of structures that we can withstand increasingly heavy weather phenomena. In this scenario, technology can be a driver for innovating cleaning methods by adopting increasingly safe and sustainable solutions. The Land Reclamation Consortium has always been focused on these issues and we are happy to have been chosen as a company that can give concrete application to the Consortium’s vision.”

Gerotto ROBOTICS

Best solutions for industrial maintenance, cleaning of storage tanks, pipelines, confined spaces, Atex zones and underwater environments.

Articles and news

Latest articles

Subscribe to the newsletter to stay updated on the latest news